Electrification

Electrification needs hardware, we fill that need.

At our sheet metal factory in Vietnam we have done countless projects related to the infrastructure of renewable energy. Below an overview of some of the products we have made, including a more detailed description of the industry and products.

Housings

Cabinets, housings, and

enclosures

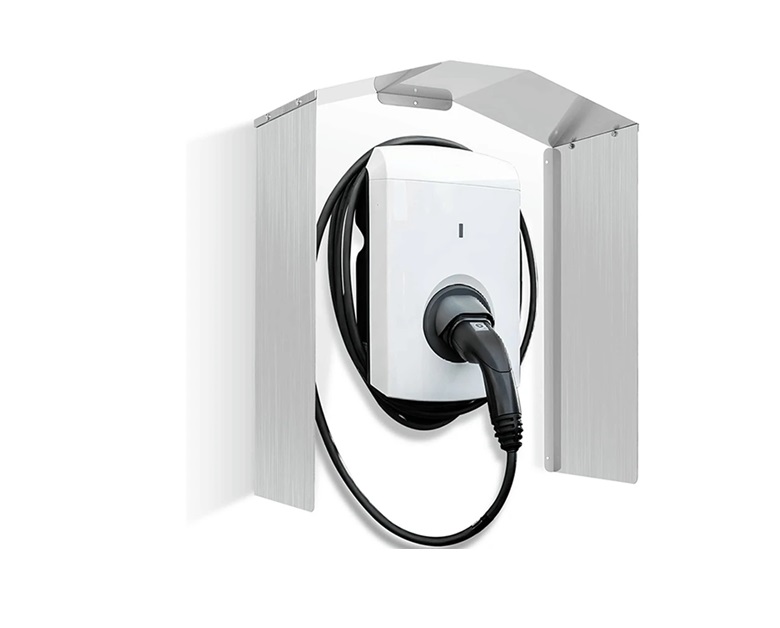

Covers

Covers to protect charging

hardware

Wall hook

Wall hooks to manage and

organize cabling

Floor mount

Floor mounts to secure and

organize EV infra

We produce products that enable electrification

One thing is sure, the future is green and we contribute to that future by producing EV charging parts. Electrification plays a key role in reducing our carbon footprint and combating climate change. As industries, transportation, and homes move from fossil fuels to electricity, the demand for clean, renewable energy sources increases.

Renewable energy drives the creation of a sustainable future by reducing reliance on fossil fuels and lowering carbon emissions. By integrating renewable energy into general mobility, especially through electric vehicles (EVs), we significantly reduce the environmental impact of transportation. Expanding EV charging infrastructure is crucial to supporting the growing number of electric cars.

The electrification parts we produce

EV charging stations, hardware, and infrastructure use several sheet metal and metal components because of their strength, durability, and conductivity. Here’s an overview of the key parts we produce:

1. Enclosures and Housings

- Charging Station Cabinets: Manufacturers typically use sheet metal (such as aluminum or steel) to construct the outer shell or cabinet of the charging station, protecting internal components from weather, vandalism, and other environmental factors.

- Mounting Poles and Stands: Manufacturers often use steel or aluminum to create mounting poles and stands, providing structural support and stability for the charging units.

2. Electrical Components and Conductors

- Connectors and Plugs: Manufacturers use metal, often copper or brass, in the conductive parts of charging plugs and connectors to ensure efficient power transfer between the station and the vehicle.

- Contact Plates and Terminals: The charging system relies on metal contact plates and terminals to connect power sources and efficiently transfer energy.

3. Cooling Systems and Heat Sinks

- Cooling Plates/Heat Sinks: Manufacturers equip many high-powered charging stations with metal heat sinks, usually aluminum, to dissipate the heat generated during charging.

- Cooling Fans: Manufacturers often use metal components in fan blades and other parts of active cooling systems.

4. Mounting and Support Structures

- Brackets and Fasteners: Various metal parts, such as brackets, screws, and bolts, are used to mount and secure charging equipment, both internally and externally.

- Cable Holders and Management Systems: Metal may be used to create robust holders for cable management.

5. Charger Display Panels and Covers

- Protective Frames and Bezels: The displays and control panels often have metal frames or bezels to secure and protect electronic interfaces.

6. Charging Point Signage and Fencing

- Metal Signs and Fencing: Metal signs and fences may be used to mark and protect EV charging stations for durability and visibility.

7. Transformers and Power Converters

- Transformer Housings: Metal is used in the housings of transformers to regulate voltage for charging stations.

Learn more about EV charging parts in Vietnam

Please contact us to make it happen. If you want to know more about electrification, please follow this link. For more information on other industries we serve, please visit our product page.